CSIRO stored grain researcher laboratory researcher Sylvia Allen explains the benefits of inert dusts for insect control on stored grain and how these products can be used as a successful and safe alternative to insecticides.

Refined inert dust offers grain growers a successful chemical free and long term protection option for controlling insect infestations in stored grain.

According to CSIRO Stored Grain Research Laboratory researchers, inert dusts are mineral earths which offer a range of benefits for stored grain compared to conventional insecticides.

These include low toxicity to humans and animals, long-term effectiveness against stored product insects and grain commodities which are free of chemical residues.

Inert Dust Use

Historically, the use of inert dust has been favoured for insect control because of their chemical inactivity, low toxicity, lasting persistence and local availability. As the growing demand for chemical free food products, widespread chemical resistance in stored product insects and the need to store grain for longer periods is supporting the use of refined inert dusts such as diatomite.

In Brief

- CSIRO researchers believe the use of inert dusts to prevent insect infestations in stored grain is a safe and successful alternative to insecticides.

- The advantage of inert dusts including long-term protection, low toxicity, easy of application and maintenance of grain quality. Treated grain is also free of chemical residues and safe as livestock feed.

- Inert dusts can be added to grain by an auger, order used as structural treatment for silo walls and floors and farm machinery.

- Recent research has shown inert dusts are also effective as barrier treatments against re-infestation of grain bulks.

Desiccant Dusts

Interest is now very focused on the use of desiccant or absorptive dusts for the protection of stored grain. Desiccant dusts include materials such as synthetic silica, Diatomaceous Earth, kaolinite clays, activated carbon and silica aero gels.

Some desiccant dusts will abrade and absorb the protective waxy outer layers of insects, leaving them vulnerable to dehydration and deaths in all but high humidity situations.

“When it comes to Diatomaceous Earth and Pest Control. Diatomaceous Earth takes physical action against pests. Causing insects to dry out and die by absorbing the oils and fats from the cuticle of the insect’s exoskeleton. The diatoms sharp edges are abrasive, speeding up the process. It remains effective as long as it is kept dry and undisturbed.”

Aus Diatomaceous Earth

The effectiveness of desiccant dusts is reduced in humid environments where passive movements in moisture from the atmosphere into an insect’s body appears to compensate for moisture loss due to desiccation.

In stored grain, an equilibrium relationship exists between moisture inside and outside the grain.

Typical maximum moisture contents recommended for long-term protection by inert dusts are 12% for winter cereals such as wheats, barley and oats and 14% for sorghum. Above these moisture contents the amount of water vapour surrounding grain is high enough to allow insect survival.

Storage advantages

Storers of seed an feed grain can benefit from the use of inert dusts to protect stored grain, particularly where adequately sealed storage is not available.

Inert dusts offer ease of application and maintenance of grain quality. They also leave treated commodities free of chemical residues, no withholding period is required and are safe fo animal consumption. Some products have been accepted under the organic standards certification scheme established by the National Association of Sustainable Agriculture, Australia Limited.

It is wise to investigate the limitations associated with the sale of grain treated with inert dusts since there are some disadvantages and restrictions to their use.

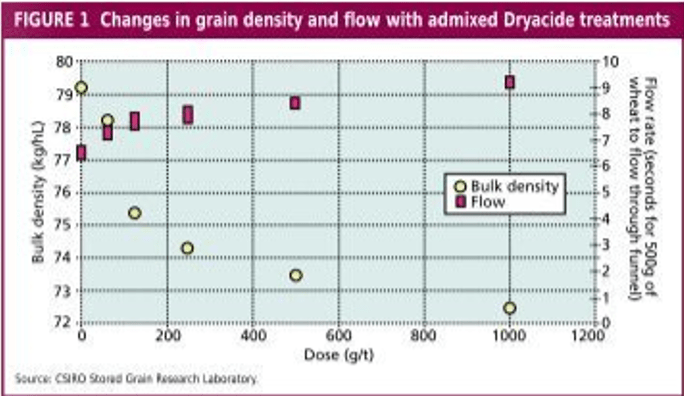

Admixture of inert dust products with grain alters some grain properties. It limites the free flowing properties of grain reducing the flow rate through handling equipment and increase bulk volume. (see figure 1)

The abrasive nature of many dusts also cause machinery and equipment sress. These are not significant factors in small farm stores but are of concern in large commercial facilities. Consequently, grain admixed with inert dusts cannot be delivered to commercial bulk handling facilities.

Application range

Diatomaceous Earths are the most common inert dusts registered for protection of grain in storage. Diatomaceous Earths are the remnants of tiny fossilised diatoms now occurring in deposits in various areas of the world.

Diatomaceous Earth also known as Diatomite, is registered as a food additive in many countries and some products based on these earths are acceptable as grain treatments under organic standards.

Dryacide and PermaGuard are Diatomaceous Earth Products currently registered for use of grain stream by auger, generally at a rate of one kilogram of dust per tonne (0.1%) or 1.5-2kg/t for heavily infested grain. Research shows Dryacide is highly effective at killing insects when applied to wheat ta these treatment rates, which is a significant decrease in the amount of mineral earth products previously required for effective insect control.

To avoid blockages during application, take care to ensure dust is admixed at an even rate into the grain stream.

Inert dusts are also suited as structural and spot treatments such as an application to walls of empty stores, to farm equipment (for example, headers and augers), treatment of wall voids and around grain stores. Inert dusts can be applied to walls and floors, either as a dry dust or water-based slurry.

The dry dust can be applied with an air gun powered by an air compressor. A hand bellows pump and extension pipe can be used to apply the dust as a dry powder.

Inert dusts applied at the rate of one gram of dust per square metre will produce a very light coating on treated structure, similar to dust settled on household furniture which as not been dusted for some time. Take care to avoid excessive application since a thick dust coating may flake off.

Some dusts can also be applied as a water-based slurry using a centrifugal pump. A slurry has the advantage of reducing the dustiness of the application procedure. Take precautions to protect eyes and respiratory passages when handling or applying inert dusts as a powder. Hand cream and gloves also can be used to protect skin from drying out. Lack of protection during application may cause symptoms such as eye soreness, irritation through inhalation and drying of the skin. Additional information is given on the product labels of commercially available dusts.

Gas Barrier

The CSIRO Stored Grain Research Laboratory has developed application methods to allow inert dusts to be used as a barrier to gas loss in fumigated grain stores.

The effectiveness of SiroFlo (a pressurised distribution system for phosphine use in partially sealed stores) can be improved by applying a thin dry blown layer of dust that acts as a cap to retard phosphine has loss.

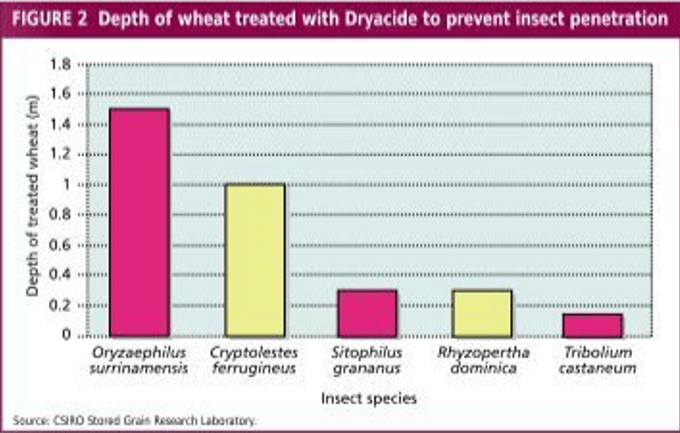

The dust coating maintains higher fumigant concentrations in the critical surface layer of grain. In addition, inert dusts can be combined with aeration, where the upper 300 millimetres of the surface is treated with an admixture of 1-2kg/t of grain. See figure 2.

Ongoing Research

Inert Dusts are a versatile and effective treatment for long-term protection of grain and structures from insect attack.

With financial support from the Grains Research and Development Corporation, the CSIRO Stored Grain Research Laboratory is continuing to research new application methods to broaden the range of uses of inert dusts and to assess the attributes of effective dusts.

Reference: Farming Ahead, No. 109 – January 2001

Leave a comment